Unser umfangreiches Robotersortiment bietet neben anwendungsbezogenen Varianten wie Schweiss-, Palettier-, Lackier- und Handling-Roboter auch Modelle für Labor- und Reinraumapplikationen sowie schlüsselfertige automatisierte Schweißsysteme höchster Qualität.

Logistics

Yaskawa Deutschland Anwendungen Nach Branchen Logistics

Überblick

Motoman Robots in Logistics, Warehouses and Retail Distribution Centers

Basic Robotic Applications in Logistics

Piece Picking with Motoman Robots (Goods-to-Picker)

Piece Picking is a growing application category in warehouses, due to the exciting breakthrough of machine vision technology. This technology addresses the typical warehouse requirement of having a high variety of SKUs to be picked. With classical Vision systems, every single part variant needs to be teached in upfront, which is a high organisational burden for commissioning. With AI (neural network based) part recognition software, after an initial training phase where the software build up it's own decision criteria, parts can be picked which have never seen by the vision system before. In addition to the part recognition part, a good Robotic AI Vision software has to include robot motion, approach and pick algorithms. On the one hand, YASKAWA are supporting the exciting startup playfield in this technology all over the world, where the ides and technology mockups are born. On the other hand, within our System Integrator networks, you will find experienced System Integrators who are capable to turn your idea into a into 24/7 stable and reliable application.

Large E-Commerce and FMCG Retailers count on Good-to-Picker principle in their warehouses - using a fleet of mobile platforms without robotic arms, and moving the goods in shelves or on conveyors to very versatile stationary robotic piece pickers.

Single Piece Picking with Motoman Robots (Picker-to-Goods)

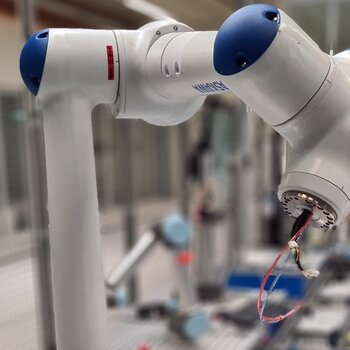

Moving robot pickers with arms between goods means Mobile Robot Technology. Although many pilots have been presented, almost no real real robotic Single Piece Picker-to-Goods applications are still out there, because of poor ROI due to low pick rates, costly commissioning, safety consideration in an environment with humans, and demanding vision technology requirements. This may change with our new HC10 and HC20 Cobots, which have the right reach and payload to put on a mobile platform.

Case Picking with Motoman Robots (Goods to Picker)

Case Picking is a growing applciation category in warehouses, based on classical Pick / Place / Palletizing Packaging Industry machinery, but supplemented by exciting machine vision technology.

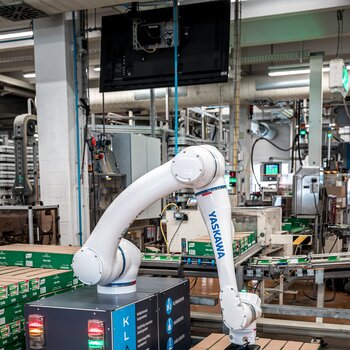

Palletizing with Motoman Robots

Typically installed at the end of an outlet conveyor coming from a storage area, Motoman Robots are able to pick up the goods and palletize them on open pallets or other load carriers. For more palletizing applications, see our "Palletizing" Application section of our web page.

Depalletizing (Multi-SKU) with Motoman Robots

With today's vision technology, Depalletizing of random boxes is feasable and reliable. Motoman Robots provide excellent and fast cycle interfaces to advanced 3D Machine Vision Systems for perfect integrations.

Copacking (3rd Party Logistics)

Unpacking is interesting for Logistics / Contract Packagers ("Copackers"), who are companies packaging products in tailored sizes for their clients. The packaging and labeling services can be used for many types of products including foods, pharmaceuticals, household products, and industrial products.

Intralogistics with Motoman Robots

E-Commerce, Warehouses and Order Fulfilment with Motoman Robots

Postal Automation

Robotic Loading and Unloading of Freight Containers

People have thought of using Industrial Robots for loading and unloading freight containers, Trucks and planes. YASKAWA Motoman have been leaders in such pilot projects, however the breakthrough is not yet there, and if there is any automation out there, it is done with dedicated semi-automatic machines today.

But - Motoman Robots - combined with a clever load building software or downstream part flow concept - are back in the game again in the next downstream step, when it comes to palletize the items coming out of the container on a conveyor belt !